Universal Sockets: A Dangerous Convenience

The Plugs and Sockets, etc. (Safety) Regulations 1994 control the selling of mains sockets in the UK. Universal sockets do not meet the requirements specified, and it is therefore not legal to supply them in the UK – despite the high praise of some media. David Peacock and Tim Hobbs explain:

- Universal sockets do not meet legal requirements for sale in the UK

- Universal sockets fail to provide safe and compliant operation

- Inconsistent voltage and lack of proper protection and grounding

- Unable to accommodate different plug sizes and shapes, often allow for mis-insertion

- Not suitable for use with UK ring circuits, can pose a fire hazard

- Positive portrayal in media shows lack of understanding of safety standards

- US army has banned Chinese-made power strips with universal sockets due to safety concerns

- Increased popularity creates challenges for responsible electrical businesses

- Important for businesses to educate clients about safety risks and provide alternative solutions

- Electrical contractors and installers should reject requests to install universal sockets.

In the 1990s the European Committee for Electrotechnical Standardisation (CENELEC) was put under pressure by the European Commission to devise a harmonised plug and socket system for Europe.

CENELEC invested considerable time in attempting to modify the design of IEC 60906-1 to guarantee safe operations with European plug types. However, it proved unfeasible to develop a system that would simultaneously cater to the safety requirements and legal regulations associated with multiple plug types. Despite this difficulty, Chinese businesses still went ahead and introduced the dangerous ‘Universal Socket’.

A company based in Taiwan asserts that it is the originator of the multifunctional power outlet, manufacturing various models capable of accommodating up to 20 different types of plugs. Nevertheless, when considering safety precautions, the response tends to be negative.

This company asserts adherence to IEC 60884-1 and CE certification for their versatile products, yet does not obtain BSI certification. Nevertheless, their sockets bear the CE mark, despite the fact that each EU country adheres to its own specific standards for mains sockets. Furthermore, CE marking is not applicable to domestic plugs and socket outlets; however, it remains mandatory for equipment incorporating plugs and sockets.

IEC 60884-1 establishes general guidelines for electrical plugs and outlets used in multiple regions, whereas national standards, such as BS 1363:1984 onwards, define plug and socket models tailored to specific countries in accordance with IEC 60884-1.

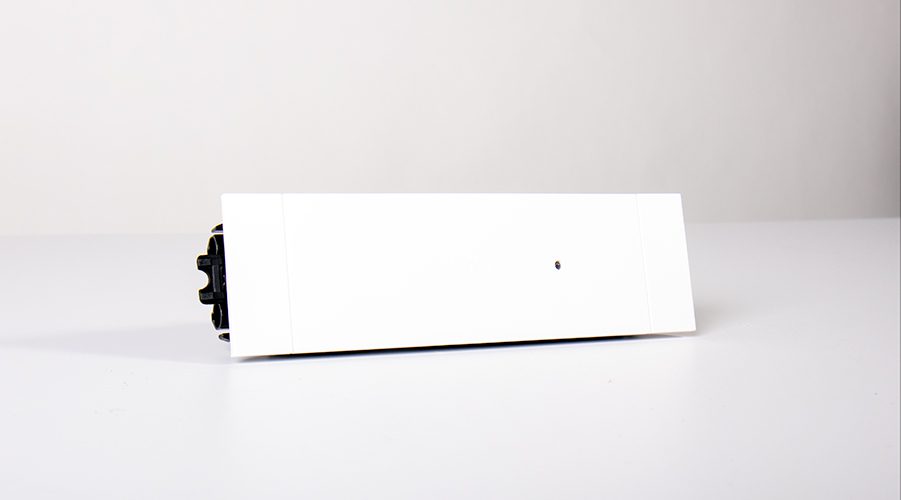

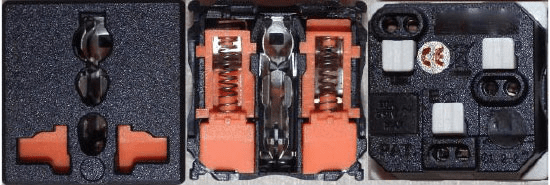

Fig 1 shows three views of a Taiwanese universal socket, the centre image, with the faceplate removed, illustrates how the shutters operate independently, contrary to the provisions of BS 1363 and IEC 60884-1. The rear image shows the illegal CE marking (highlighted). The rating marked on this socket is 20A, which is outside the IEC 60884-1 permitted maximum for screwless terminals.

Varying voltages

The issue of varying voltages is one of the reasons why universal sockets cannot be considered completely safe. These sockets are designed to accommodate plugs that operate at different voltages, which results in inconsistencies in polarity, inadequate protection against live parts, and a lack of grounding contacts for many supposedly compatible plugs. Additionally, universal sockets do not ensure reliable connections for the wide range of plug pins they accept, and they lack the necessary stability for heavier plugs and power cubes with built-in pins. Furthermore, they often lead to incorrect plug insertion, such as a Europlug or Schuko being placed between the live and earth instead of the live and neutral. The design of universal sockets also poses a problem when connected to a 32A ring circuit, as they accept unfused plugs. The PlugSafe campaign raised concerns about the misguided recognition of universal sockets in May 2012, when a BBC segment showcased them without fully understanding the safety implications and the reasons behind the use of different sockets in different countries.

It appears that, at the BBC, there was a lack of consultation with an engineer regarding a device that received high praise but did not meet the necessary safety requirements for a UK plug. For those unfamiliar with the design, the main issues involved an accessible fuse holder while the plug was in use, as well as the ability to insert the plug into a socket without the side flaps engaged, leaving no protection against a child inserting a pin or similar object into the live contacts alongside the pins. Interestingly, the founder of the BBC, Lord Reith, introduced the process in 1942 that ultimately led to the development of the very safe BS 1363 fused plug and socket design.

In 2012, due to the implementation of our program, PlugSafe was able to acquire samples of wall-mounting universal sockets from various online suppliers in the United Kingdom. Our investigations unveiled a number of issues with these devices (outlined below), prompting us to approach Edinburgh Trading Standards for assistance in evaluating a product manufactured by a Chinese company in September 2012. Consequently, the outcome was an obligatory removal of the product from the market in February 2013, as documented on RAPEX under the reference A12/0135/13.

The decision to recall the product led to proactive measures taken by Edinburgh Trading Standards and other relevant entities to remove similar items from circulation. Additionally, the Electrical Safety Council (now known as Electrical Safety First) instigated a thorough investigation conducted by Nemko Ltd. The comprehensive findings of this investigation were subsequently published in the summer 2013 edition of “Switched On” magazine.

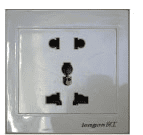

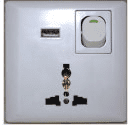

Fig 2 shows (left) the actual Lengon socket submitted for test by Edinburgh Trading Standards, while Fig 3 shows an unbranded universal socket incorporating a USB supply – the live apertures are too close to the edge.

Fig 2 shows (left) the actual Lengon socket submitted for test by Edinburgh Trading Standards, while Fig 3 shows an unbranded universal socket incorporating a USB supply – the live apertures are too close to the edge.

Un-earthed and potentially dangerous

A fundamental reason for not using a single plug type is that there are two very different mains voltages used in the world. Europe uses a nominal 230V, and America is a nominal 120V. The ability to be able to connect a 120V plug into a universal socket connected to a 230V supply is non-compliant with IEC 60884-1, and could cause the connected appliance to overheat or even catch fire.

Every universal socket examined by PlugSafe has the live terminal arranged to suit a BS 1363 plug, and that automatically means that when an earthed US plug is inserted into the same contacts it is connected with the wrong polarity.

Standard US mains sockets have a neutral aperture, which is wider than the live aperture to ensure the correct insertion of two-pin plugs. As there is no earth pin to establish correct polarity in a two-pin US plug, a wider neutral blade is used for polarity sensitive applications. In universal sockets both live and neutral apertures will usually accept the neutral blade.

Un-earthed and potentially dangerous German Schuko plugs use a side contact in a recessed socket for earthing, while the French plug uses an earth pin projecting from the face of the socket. Clearly, neither of these contacts exist in a universal socket (the presence of either would prevent other plugs being used) so, although the universal socket will accept both French and German plugs, neither will be earthed! In the event of a fault this is also a potentially lethal situation.

Many plugs, including BS 1363, have partially sleeved live and neutral pins to ensure that the live pins cannot be touched when the plug is partially engaged. Other plugs, such as the German Schuko, rely on the plug being inserted into a recessed socket. As universal sockets can have no recess, there is nothing to prevent touching an unsleeved energized pin on a partially engaged plug.

The BS 1363 standard requires that pin apertures are shuttered, the shutters being operated either by insertion of the earth pin or by simultaneous insertion of two or more pins. Some universal sockets have no shutters; others have inadequate shutters, which can be opened by pressing a pin or other object into the live aperture alone. This is completely unacceptable and potentially lethal. We have not yet found a shutter system in a universal socket, which would satisfy the UK requirements.

Fig 4 (left) shows a universal socket, clearly intended for the UK market, showing ineffective shutters, which allow insertion of a paperclip without the shutter even moving. Fig 5 shows a universal socket with no shutters.

Fig 4 (left) shows a universal socket, clearly intended for the UK market, showing ineffective shutters, which allow insertion of a paperclip without the shutter even moving. Fig 5 shows a universal socket with no shutters.

Many different pins so no BS 1363 compliance.

The pin apertures in universal sockets do not adhere to BS 1363 standards, accommodating different types of pins. The closely spaced live pins of US plugs measure 12.7 mm, whereas UK plugs have pins spaced 22.2 mm apart. US plugs typically have a width of 22-25 mm. However, a minimum distance of 29 mm between socket aperture edges is needed to accommodate a UK plug. Therefore, inserting a US plug into a socket designed for UK plugs exposes the socket apertures on both sides, posing a danger of electrocution, especially for children.

In the United Kingdom, there are concerns regarding the level of protection offered by ring circuits for flexible appliance cords. When non-BS 1363 plugs are used on universal sockets connected to a UK ring circuit, it can result in cords being at risk of overheating and causing fire hazards. Additionally, numerous universal sockets exhibit substandard construction quality, thereby raising safety concerns. Such sockets often lack proper contact with plug pins, leading to arcing, overheating, and potential fire hazards.

The socket’s role in securely holding the plug is hindered by oversized openings and poor connections in universal sockets. Certain plug types, like the German Schuko, lack the added stability provided by the socket’s recess in universal sockets. The oversized openings of universal sockets can lead to incorrect plug insertion, such as between live and earth contacts. The US army has banned the use of power strips with universal sockets made in China in South West Asia due to incidents involving electrocutions and electrical fires.

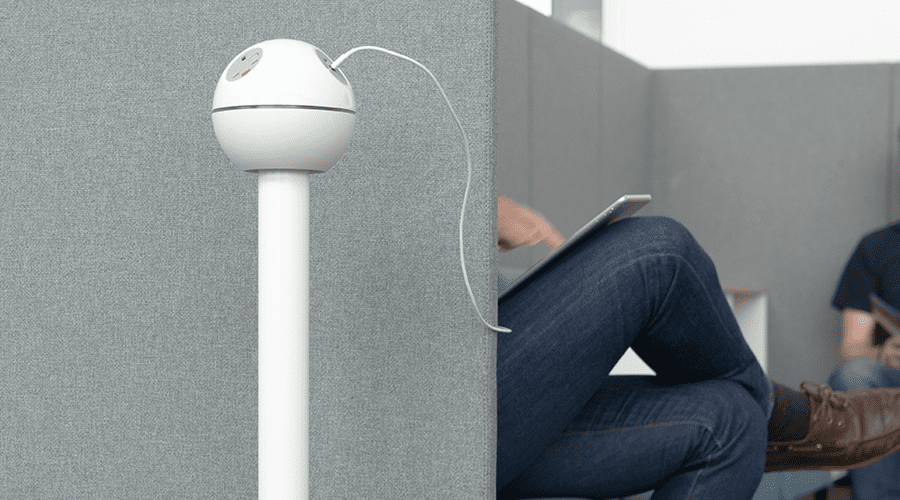

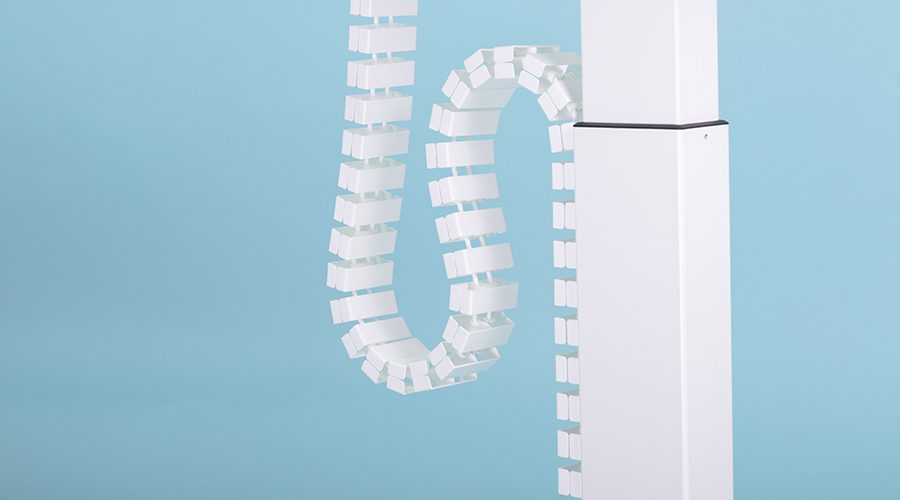

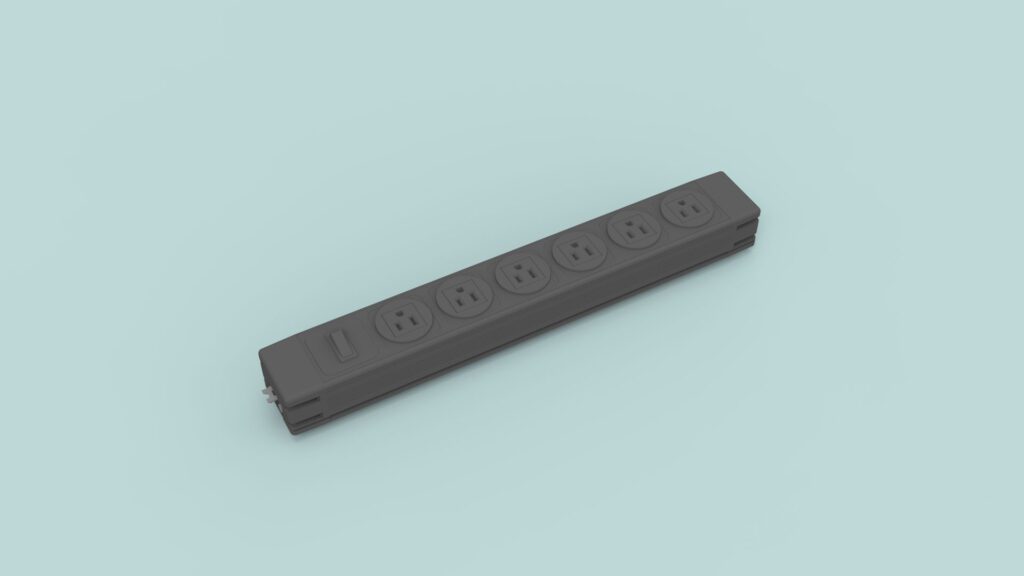

The increasing awareness of universal sockets among travelers abroad, along with misleading articles in the media praising the universal socket as a one-size-fits-all solution for electrical needs, is causing difficulties for responsible electrical companies. For over 27 years, OE has been a trusted manufacturer of reliable soft-wiring power modules and cable management solutions for the international commercial office industry. Throughout this time, we have consistently equipped our modules with sockets that are certified for specific countries.

Nevertheless, in recent years, there has been a large influx of universal sockets coming from China. Despite being proven to be inherently unsafe, the appeal of a universal power outlet remains strong among consumers.

Alternative solutions

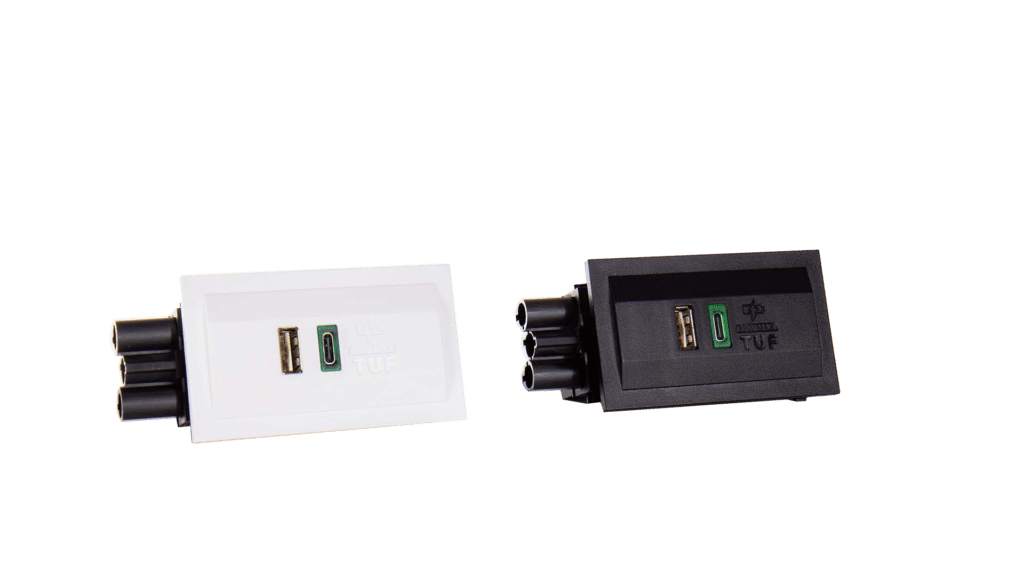

With representatives on various UK, Australian, and International Standards Committees, OE has been obliged to respond to requests for universal sockets by providing an explanation of the associated concerns. In such cases, we propose alternative solutions, such as the utilization of compliant sockets or, in scenarios involving the charging of handheld devices, the implementation of TUF (USB) Chargers, which inevitably carry a higher price.

Inquiries arise from two channels: within Europe and outside. Addressing concerns within Europe is straightforward. Businesses understand the importance of compliance, especially in Health and Safety. It is crucial to explain that products with universal sockets do not meet the necessary standards and cannot bear the CE mark or be legally sold.

Outside Europe, there is no CE marking scheme, making it easier for unaccountable manufacturers to distribute non-compliant products. Universal socket modules, often from China, are cheaper but may not meet the necessary standards.

Enforcement of standards is done through reporting to Trading Standards. However, universal sockets in airports and less developed countries have become more common. Travelers unfamiliar with regulations may see these sockets as acceptable and not report them upon returning due to perceived usefulness. They don’t realize that many travel adaptors are also non-compliant.

OE acknowledges the need for technical guidance, but sales and technical staff are spending more time educating clients. Despite this, some clients still insist on universal socket solutions and go elsewhere, especially those outside of Europe.

Effectively the universal socket is not only non-compliant, uncertifiable and unsafe, its existence also wastes manufacturers significant amounts of time, loses sales and costs profits.

As a UK manufacturer and supporter of ‘Made in Britain’, with a customer base extending across the globe, OE has always been proud of its reputation of being able to say ‘Yes’ and provide a compliant solution for any customer requirement – but increasingly it is having to say ‘No’ to some clients simply because they ‘believe’ that there is a universal power solution.

In conclusion:

The Plugs and Sockets, etc. (Safety) Regulations 1994 regulate the sale of mains sockets in the UK. Universal sockets don’t meet the specified requirements and are illegal to supply in the UK. Some suppliers continue to sell them despite Trading Standards’ efforts. Electrical contractors and installers must be vigilant and refuse to install these hazardous fittings.

Further information:

PlugSafe information site on Universal Sockets: www.universalsocket.org.uk

Author biographies:

David Peacock (david@plugsafe.org.uk) is a retired engineer, a founding member of PlugSafe, and one of the founders of FatallyFlawed, the campaign to raise awareness of the dangers associated with socket covers in the UK

Tim Hobbs (tim.hobbs@oeelectrics.co.uk) has been Technical Director/Owner of British manufacturer OE Electrics for over 21 years, providing soft-wiring solutions for commercial offices, hospitality and education.